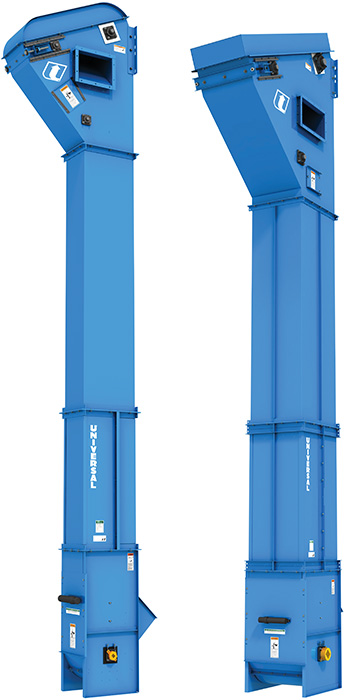

Our material handling equipment is best known for the two most encapsulating industries that we serve: the Agricultural Market and the Industrial Market. While these are the two largest industries that we serve, we proudly serve many other markets that may not conform to these two categories. If you’re not sure which equipment would best suit your material, give us a call and our sales staff would be happy to help you find the elevator/conveyor that best fits your requirements.

In the agricultural market, we’re well known for our diverse line of equipment, offering either gentle handling or high speed options. Designed to handle products such as seed, grain, edible beans, popcorn, peanuts, etc., our equipment minimizes mechanical damage to the product and can ensure that your product reaches its destination in the most efficient & effective manner possible.