The development of the Universal Industries bucket elevator is the culmination of customer feedback and industry research into the request for a better solution to handle specific materials. Universal Industries continuously strives to exceed customers expectations to design and manufacture the best result for your material handling needs.

Bucket Elevators / Seed & Grain Legs

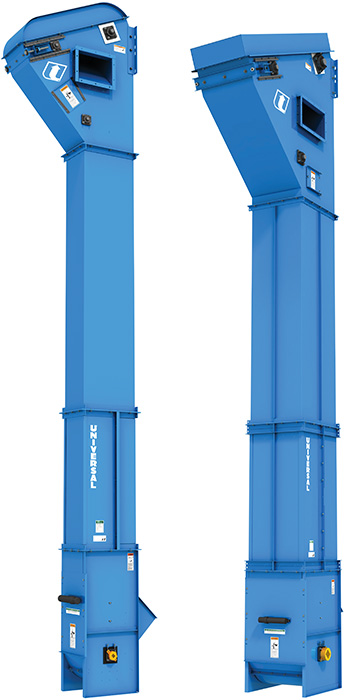

Twin Trunk Alpha Series

Alpha Series bucket elevators and grain legs are perfect for gently handling bulk products. The Alpha Series model offers an EASY DUMP® capacity rating that utilizes gravity discharge techniques to reduce product damage, and are available in different capacities and speeds and bucket types.

G Series

G Series elevators are twin trunk casing, centrifugal discharge elevators. The head contour, pulley diameter, bucket size, and belt speed have been carefully selected to maximize capacity and minimize product damage during the discharge when moving peanuts in the shell and other lightweight materials.

P Series

Even more gentle than our Alpha Series, the P Series elevators excels at gently handling materials that are subject to impact damage, such as edible beans or food products. The weather-tight, dust-tight construction and innovative boot design is carefully fitted to assure superior and continuous clean-out.

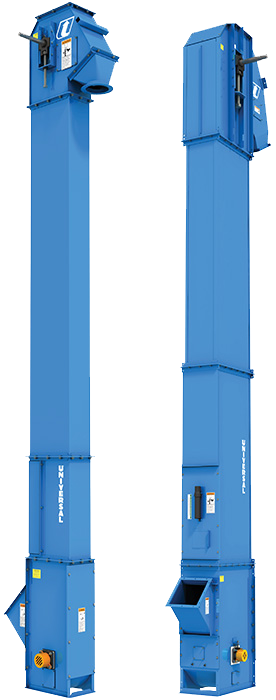

U Series

U Series bucket elevators utilize a single trunk casing and are built with thicker steel to handle corrosive, abrasive and hostile materials. When the elevator experiences extreme temperatures and/or additional harsh material characteristics, we offer a chain option.

U Series models offer an EASY DUMP® capacity rating that utilizes gravity discharge techniques to reduce product damage.

Top Take-Up U Series

Our Top Take-up U Series elevators are constructed with the take-up system in the head casing rather than the boot. This design allows for a curved bottom boot to reduce product build up and offers a better seal for fine and dusty materials.

U Series models offer an EASY DUMP® capacity rating that utilizes gravity discharge techniques to reduce product damage.

SC Series

Our SC elevator is ideal for processing plants for food and other bulk solids and for processes that require impeccable sanitation and inspection. The front side panels open quickly for inspection and for cleaning inside the casing, as well as belt removal.

For demanding installations, we offer special belts and buckets. The heavy support column and a massive base plate make this a rigid, self-supporting elevator.

UniMAX® Series Bucket Elevator

The UniMAX® bucket elevator is a high capacity centrifugal discharge elevator engineered to meet the most strict industry standards. The elevator head, boot, and intermediate sections have been designed with adequate space for buckets and belt to travel un-impeded throughout the system. Bucket spacing and belt speeds follow recommendations and standards set forth by industry leaders. UniMAX® bucket elevators are designed with cleanliness in mind by eliminating shelves for material to build up in the head, inspection doors, vents, access and boot section. The casings were also designed for afterthought installation of hazardous monitoring equipment to eliminate cutting and grinding on newly purchased elevators.

Safety is priority – UniMAX® elevators are built with the provisions to install hazardous monitoring equipment. The boot and head casings have removable covers to install belt alignment sensors and boot shafts are drilled and tapped for speed sensors. The boot bearing guards offer a take up location indicator and knock outs to access grease zerks and installation of bearing temperature sensors.

What is the difference between a grain leg and a bucket elevator?

A “grain leg” is the agricultural term for a bucket elevator. Both lift material vertically using buckets attached to a moving belt or chain inside an enclosure. Differences are mostly in spec and options: ag legs emphasize grain/seed handling, dust control, gentle handling, and service access; industrial elevators add heavier-duty components.

How do I size a bucket elevator for small grains?

Start with required capacity (tph or bph) and material properties (bulk density, flowability). Use selection charts to choose bucket size/spacing, belt speed, and head pulley diameter that meet capacity at ~70–85% bucket fill. For small grains/seed, prioritize gentle handling: slower speeds, appropriate cup style, and clearances to limit damage.

What’s typical lead time and maintenance for belt conveyors?

Lead times vary by season, configuration, and materials; plan several weeks for standard units and longer for stainless or custom options. Routine maintenance is simple: check belt tension/track, inspect idlers and bearings, verify skirting/seals, clean spillage, and service motor/gearbox on schedule. Document checks and lubricate per the equipment manual.

When does stainless make sense for fertilizer applications?

Dry fertilizers (urea, potash, NPK blends) are hygroscopic and corrosive; even minor moisture accelerates rust on carbon steel. Stainless—full units or contact-surface upgrades—extends service life, improves cleanability, and cuts unplanned downtime. Choose stainless for corrosive products, washdown or coastal environments, or when life-cycle cost outweighs higher upfront price.